Hot Selling For Spray Jets - DLC Coating Fuel Pump Plunger With High Strength And Wear Resistance – Weikun

Hot Selling For Spray Jets - DLC Coating Fuel Pump Plunger With High Strength And Wear Resistance – Weikun Detail:

Advantages

● With the help of a pair of plungers, it is possible not only to ensure the supply of high-pressure fuel and its dosage, but also to determine the appropriate fuel injection mode.

● Maximum economy with high efficiency.

● High environmental friendliness due to the combustion of a smaller portion of fuel and its high-quality spraying into the cylinders.

Description

The plunger itself acts as a fuel displacer from the bushing cavity. This element is used to create high pressure in the fuel supply system line.

However, plunger assemblies are the main element of injection pumps, which are widely used in diesel engines. It is distinguished by its impressive simplicity of design, durability and reliability.

In addition, plunger pairs are two small parts that go into a high pressure fuel pump (injection pump) device. The first is called a plunger and is represented as a thick, recessed finger. The second is the plunger sleeve and it looks like a thick-walled sleeve into which the first part is inserted.

Features

First, it is worth considering that a diesel engine runs on a special fuel, which can contain a large number of microscopic particles. If you use low-quality diesel fuel, then the gap between the plunger and the bushing may increase due to the content of abrasive particles, water and other impurities in the diesel fuel.

Therefore, the only service that a car owner can perform is to monitor the quality of the fuel, prevent condensation in the line and change the filter in ti At first glance, the presence of water droplets in diesel fuel does not seem so critical, but because of this, the fuel film in the gap of the plunger pair will collapse, and the mechanism will not be able to create an appropriate pressure. Also, diesel oil lubricates the surfaces of parts, preventing friction when dry, and protecting the device from overheating.

Moreover, if the fuel filter is not changed in time, its element may burst. Because of this, dirty fuel will be pumped through the pump, in which small particles may be present. In this case, there is a high probability of pump failure, since the plunger pair will simply jam.

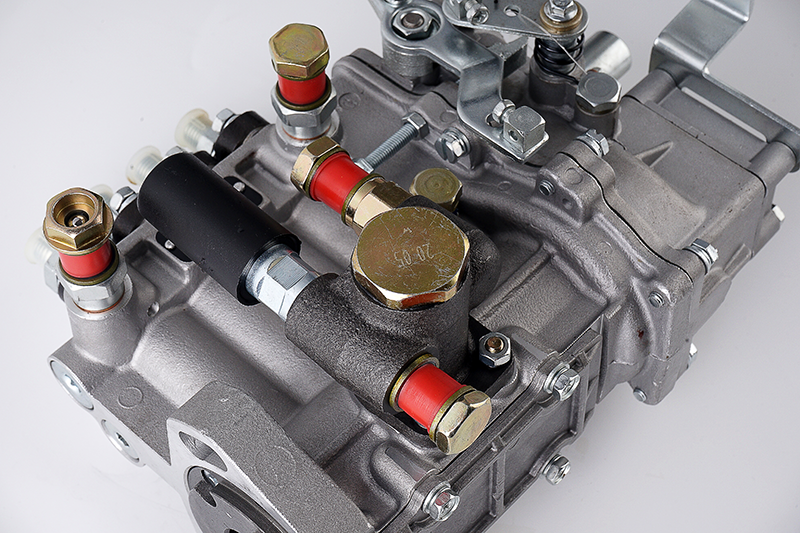

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff as well as consistent purpose of reputation first, client first for Hot Selling For Spray Jets - DLC Coating Fuel Pump Plunger With High Strength And Wear Resistance – Weikun , The product will supply to all over the world, such as: Vietnam, French, Guatemala, Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.