Hot New Products Plunger Injection Pump - EuroⅢ Emission Series Valve Assembly Model No.FOOR J02 410 – Weikun

Hot New Products Plunger Injection Pump - EuroⅢ Emission Series Valve Assembly Model No.FOOR J02 410 – Weikun Detail:

Advantages

● Providing stable performance and high efficiency.

● Reducing fuel consuming rate.

● Benefiting engine service time.

● Being superior in material and excellent in workmanship.

Description

A valve assembly is a complete valve mechanism including all peripheral devices directly related to the installation and functioning of the valve. Plus, the valve assembly is the controlling component of the injector. A valve assembly typically includes the entire fluid control mechanism and its housing, electronic or mechanical actuation mechanism, and any associated connectors, as well as external sensors and fasteners. The engine injector is mainly composed of an injector body, a pressure spring and a valve assembly. The injector valve assembly is used for opening and closing.

In some cases, valve assemblies are equipped with auxiliary equipment such as mounting adapter sleeves, gasket selection, and spare seals. The valve assembly is the core component of the injector. The valve assembly is composed of a pair of slide valve and cone valve, though the two processing technology is different.

Features

The valve assembly is one of the main moving parts to control the oil return of the injector. It is composed of the valve seat and the ball valve. The gap between the two is only 3 to 6 microns. It can be said that the valve assembly and stem are the core of the entire injector, but also the highest rate of damage. This place is also known as the control room, which mainly controls the injection and return of oil.

When checking the valve cap, we often use a microscope to observe whether the contact surface between the valve cap and the ball is worn. If so, it must be replaced. The top of the stem and bonnet contact is originally silver white. When it turns paper white, it must be replaced. In addition, the two small holes in the bonnet are very easy to block.

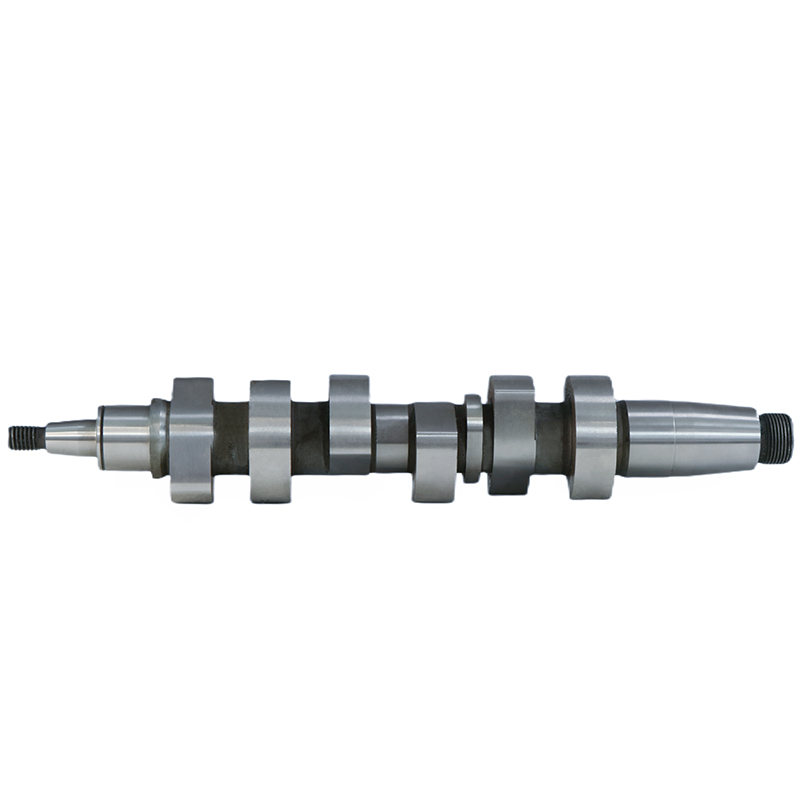

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Hot New Products Plunger Injection Pump - EuroⅢ Emission Series Valve Assembly Model No.FOOR J02 410 – Weikun , The product will supply to all over the world, such as: Jakarta, Japan, Porto, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. Your satisfaction is our happiness.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!