High Definition Plunger Fuel Injection Pump - Micro Cultivator Simplex Cylinder Pump Of Applicable Fuel Injection Model – Weikun

High Definition Plunger Fuel Injection Pump - Micro Cultivator Simplex Cylinder Pump Of Applicable Fuel Injection Model – Weikun Detail:

Advantages

● Its simple design makes it easier to use, repair, and maintain

● Its cost also tends to be lower due to a lower number of moving parts

● It has convenient flow regulation.

Description

Single cylinder plunger pump refer to as single cylinder pump, it has only one or the equivalent of a plunger pump. As the name suggests, it has only one working cylinder. Single cylinder plunger pump is a reciprocating pump, it belongs to the volume pump. The plunger is driven by the eccentric rotation of the pump shaft for reciprocating motion. Plus, its suction valve and discharge valve are unidirectional.

The working principle of the single cylinder pump is as follows:

When the plunger is pulled out, the pressure in ‘the working room’ is reduced, and the outlet valve will be closed. As it is below the inlet pressure, the inlet valve will open and the liquid will enter. However, after the plunger is pushed in, the pressure in ‘the working room’ increases and the inlet valve closes. Moreover, when it is above the outlet pressure, the outlet valve opens and the liquid is discharged.

Single cylinder piston pump is divided into two representative structure forms which are axial piston pump and radial piston pump. As radial piston pump belongs to a new type of high efficiency pump with high technical content, radial piston pump will become an important part of the application with the continuous acceleration of localization.

Features

The Single cylinder pump hydraulic system flow is 63L/min, and double cylinder pump hydraulic system flow is 100L/min. In addition, single cylinder pump hydraulic tank volume is 160L, and double cylinder pump hydraulic tank volume is 260L.

Here is more information about the cylinder pump parts:

The crane with single cylinder pump is the basic arm, and the crane with double cylinder pump is the extended arm. There are 1.5 meters between general single cylinder pump basic arm and double cylinder pump extended arm.

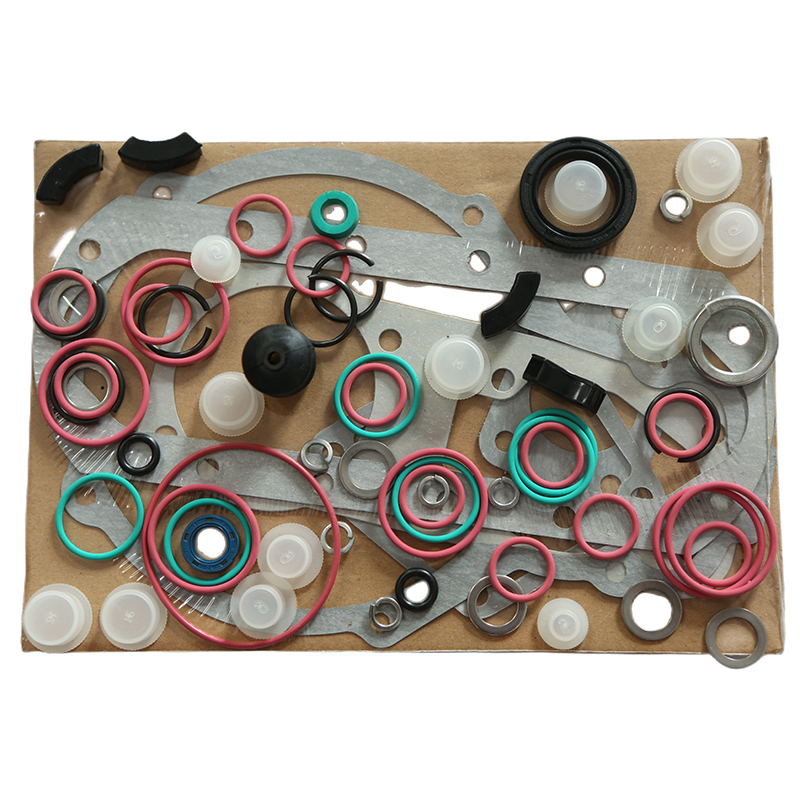

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for High Definition Plunger Fuel Injection Pump - Micro Cultivator Simplex Cylinder Pump Of Applicable Fuel Injection Model – Weikun , The product will supply to all over the world, such as: Belarus, Riyadh, Finland, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.