Excellent Quality Fuel Injection Pump 8500 Series Camshaft - Injector Connecting Rod With Model Number FOOR J02543 D29034-0901 – Weikun

Excellent Quality Fuel Injection Pump 8500 Series Camshaft - Injector Connecting Rod With Model Number FOOR J02543 D29034-0901 – Weikun Detail:

Advantages

● Its offset and fine-toothed design helps hold the bonnet in place and relieves stress on the connecting rod bolts.

● Its material is durable and wear-resistant.

● It has good applicability and high matching degree.

Description

The connecting rod is generally abbreviated to con-rod. Connecting rods are commonly made from cast aluminum alloy and are designed to withstand dynamic stresses from combustion and piston movement. A longer rod makes more torque with the same piston force, and since it’s less angular than a shorter rod, it reduces sidewall loading and decreases friction. All of this adds up to more power.

The connecting rod is mounted on the crank pin of the crankshaft with a plain bearing. The connecting rod bearing cap is bolted to the big end. The con-rod connects the piston to the crankshaft to transfer combustion pressure to the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form and in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end, so that it can improve the engine’s efficiency.

If the rod breaks while the piston is on its way up, the piston keeps going up until it jams itself permanently into the cylinder head. If the rod breaks while the piston is coming down, the broken rod can pierce a hole right through the engine block (like a compound bone fracture breaking through the skin).

Features

The connecting rod provides the mechanical linkage between piston and crankshaft and must exhibit properties of high strength, low inertial mass, and uniformity of mass with the other connecting rods attached to the crankshaft.

Connecting rods are built to withstand extreme forces, engine temperatures and pressures. However, the rebuilt connecting rod wouldn’t lasts forever. The two typical engine repairs needed from a broken connecting rod are either to the cylinder head or to the engine block itself.

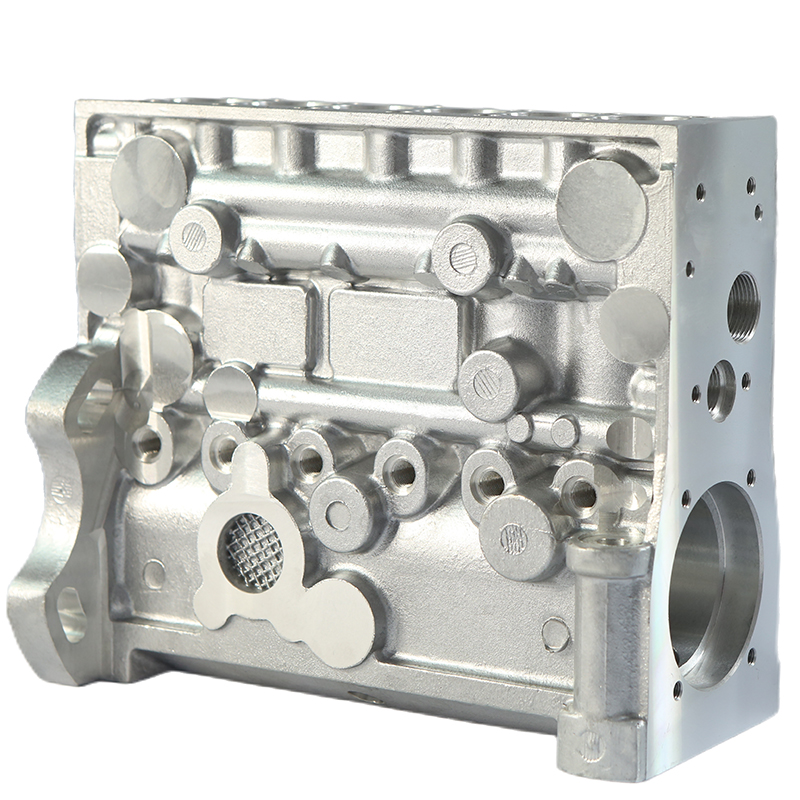

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers, hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Excellent Quality Fuel Injection Pump 8500 Series Camshaft - Injector Connecting Rod With Model Number FOOR J02543 D29034-0901 – Weikun , The product will supply to all over the world, such as: Albania, South Africa, New Delhi, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!