2021 High Quality Fuel Pump Replacement Kit - Diesel Engine Fuel Pump Injector Nozzle Model No.L204PBA – Weikun

2021 High Quality Fuel Pump Replacement Kit - Diesel Engine Fuel Pump Injector Nozzle Model No.L204PBA – Weikun Detail:

Advantages

● It is critical to the performance and emissions of diesel engines.

● It is conducive to service life of the engine.

● It has precision production and high adaptability.

Description

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them.

An injector nozzle is a fine sprayer through which fuel is injected into an engine. The top of the injector nozzle has a lot of holes to deliver a spray of diesel fuel into the cylinder.

Design of the diesel fuel injector nozzle is critical to the performance and emissions of modern diesel engines. Some of the important injector nozzle design parameters include details of the injector seat, the injector sac and nozzle hole size and shape. These features not only affect the combustion characteristics of the diesel engine, they can also affect the stability of the emissions and performance over the lifetime of the engine and the mechanical durability of the injector.

Injector nozzles interact with Pistons in Combustion Chambers. When the Piston is drawn away from the sparkplug, the injector nozzle sprays a fuel and air mixture into the Combustion Chamber.

Features

As one of the key components of the engine, the work of the nozzle will seriously affect the performance of the engine. Clogged fuel nozzles can seriously affect car performance. The reason for the blockage is due to the deposition of carbon in the engine on the nozzle or due to impurities in the fuel blocked the nozzle pathway. Therefore, the nozzle should be carefully cleaned and tested regularly to ensure that it works well.

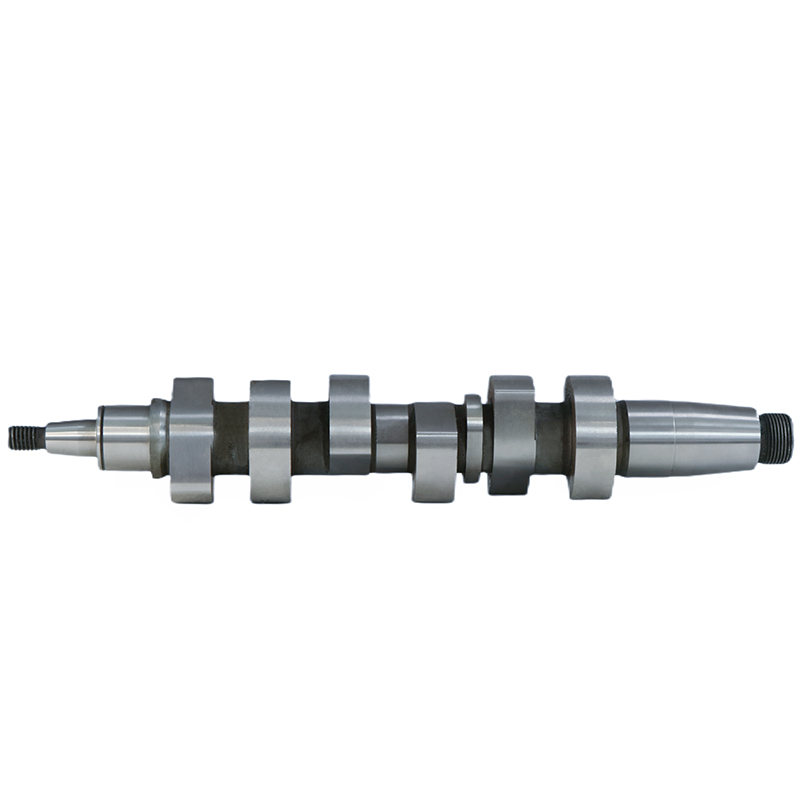

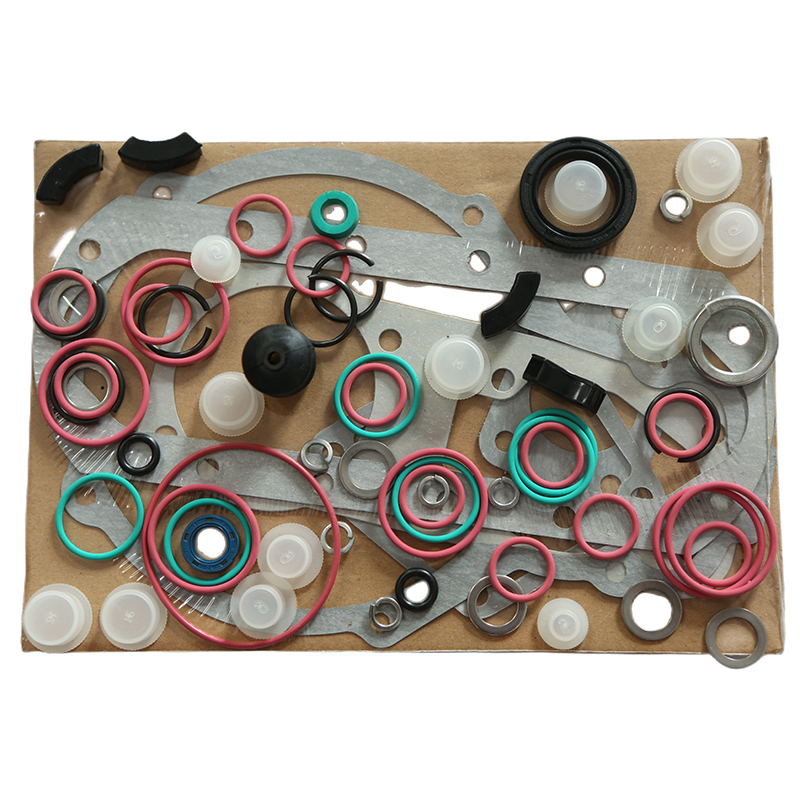

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for 2021 High Quality Fuel Pump Replacement Kit - Diesel Engine Fuel Pump Injector Nozzle Model No.L204PBA – Weikun , The product will supply to all over the world, such as: Italy, Melbourne, Madras, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!